The heating causes an oxide coating to form on the wire. To create the wire, a bar of steel is heated to a temperature of 2,200☏ (1,200☌), rolled into a long thin rod, coiled, and then allowed to cool. Raw Materialsīlunt wire with an international steel regulation of ISR 9002 is generally used to make straight pins. Today this bag is known as the pin cushion. To combat this flaw, tailors and seamstresses cleaned the rusted pins by pushing them back and forth into a bag ofĮmery grit. The nickel coating would flake off and the pins would rust. In 1843, with the help of his employees, Howe developed a machine that crimped the paper and then inserted the pins.Īlthough electroplating was invented in the mid-1800s, the process was not perfect. Workers had to manually insert the pins into paper or cards. However, the packaging step slowed down the process. In December of 1835, Howe formed the Howe Manufacturing Company, which was soon turning out about 70,000 pins daily. After the machine was exhibited at the American Institute Fair in New York City, Howe was awarded a silver medal for his contribution to manufacturing. Howe obtained a patent for his machine in June of 1832. Howe enlisted the help of a printer press designer named Robert Hoe. After watching the inmate/patients at the New York Alms House laboriously make pins by hand, he began to explore ideas for a pin-making machine. In spite of not having an official claim to this invention, the pins manufactured in Slocum's Poughkeepsie, New York factory became known as Poughkeepsie pins.Ī physician by profession, Howe also liked to tinker with machinery. American Samuel Slocum also invented a similar machine but did not patent it. In the early to mid-1800s, American inventors Seth Hunt and John Ireland Howe and British inventors Lemuel Wright and Daniel Foote-Taylor patented machines that produced pins with a solid head from a single piece of wire. These early pin factories produced just under 5,000 pins per day.Īttaching the heads presented a particular challenge. At the end of the process, the pins were polished and inserted into paper packets. In his book, Wealth of Nations, published in 1776, Smith described how one worker drew out the wire, another straightened it, a third cut the wire, the fourth sharpened one end, and another worker ground the opposite end for the attachment of the head. A "paper of pins" became a familiar cultural phrase, signifying the possessions of the simplest nature.Īt the dawn of the Industrial Revolution in the eighteenth century, noted economist Adam Smith employed the imagery of a pin factory as the perfect example of the intricate division of labor. Descriptions of a tailor's equipment from Spanish books dating back to this period included the mention of pins. The craft of tailoring was also well-established by this time. The use of iron wire, still applied during modern times, began as early as the fifteenth century in France.

The clothes of medieval Europeans were adorned with pins of many materials including bone, ivory, silver, gold, and brass. In ancient Egypt, pins were crafted of bronze with decorative heads. Since their ancient beginnings, human beings have devised methods for securing cloth together. It is used to fasten pieces of cloth or paper together. Language and literature, as well as music composition content for Sibelius Software.A straight pin is a small length of stiff wire with a head at one end and a point at the other end. Language and literature, as well as music composition content for Sibelius Software. from the University of Vermont, and she has written books, study guides, and teacher materials on Music, Mary Elizabeth is a teacher, composer, and author. In addition to contributing articles to HomeQuestionsAnswered about art, literature, and Mary Elizabeth is passionate about reading, writing, and research, and has a penchant forĬorrecting misinformation on the Internet. The name upholstery pins can be used for two quite different items.

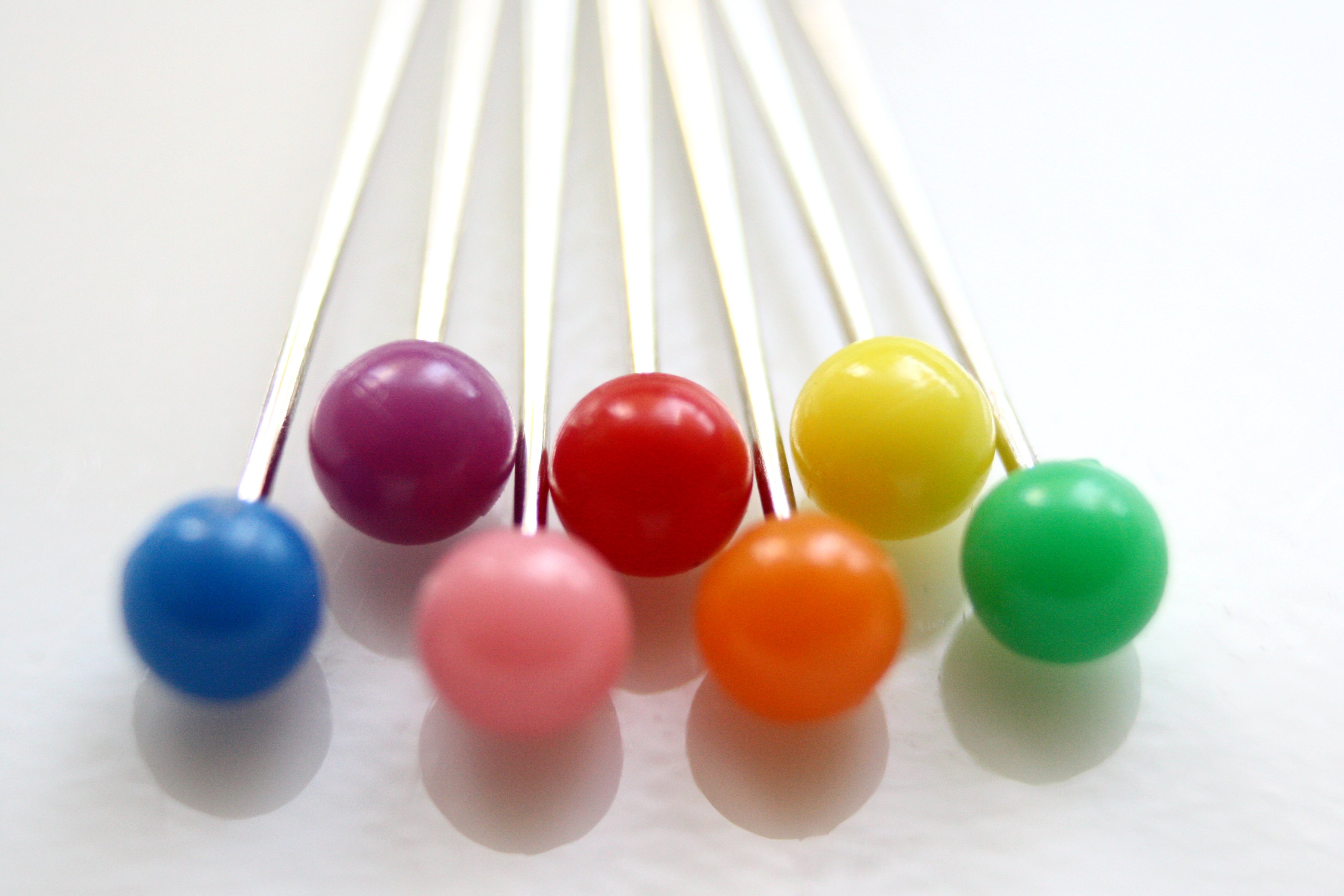

Tidy pins, also called twist pins or upholstery pins, have a top like a thumbtack and a helix shaped shaft, and are specially designed to hold slipcovers, mattress pads, and doilies in place. There are also fork pins, sometimes known as upholstery pins or loose cover pins, that are shaped like a U. Sewing pins are differentiated from specialized pins for other tasks, including quilting pins, flower or corsage pins, kilt pins, a knitting stitch holder that looks like an oversize safety pin, hat pins, bobbin lace pins, and diaper pins. Very short pins, often called appliqué and sequin or sequin pins, are some of the shortest offered. Pleating pins are a bit shorter and extra fine, suitable for delicate fabric.

Dressmaker or seamstress pins are the most common, and are designed for fabrics of light- to medium-weight. In general, longer pins tend to be thicker, made for coarser fabrics.

0 kommentar(er)

0 kommentar(er)